New Regulations On Compliance For Medical Aesthetic Injections Have Been Released, And They Will Face Stricter Supervision In 2025

With the vigorous development of the global medical aesthetics market, the safety and compliance of medical aesthetics injections have increasingly drawn the attention of regulatory authorities and consumers. The recently released 《Mesotherapy safety guidelines 2025》 clearly stipulates that all suppliers of injectable products must obtain international quality system certification, marking the official entry of the industry into a new era of "compliance is king". According to the latest 《2025 Mesotherapy Market Trends Report》, the global market size is expected to continue to maintain double-digit growth, among which hyaluronic acid and non-hyaluronic acid products will show differentiated development paths.

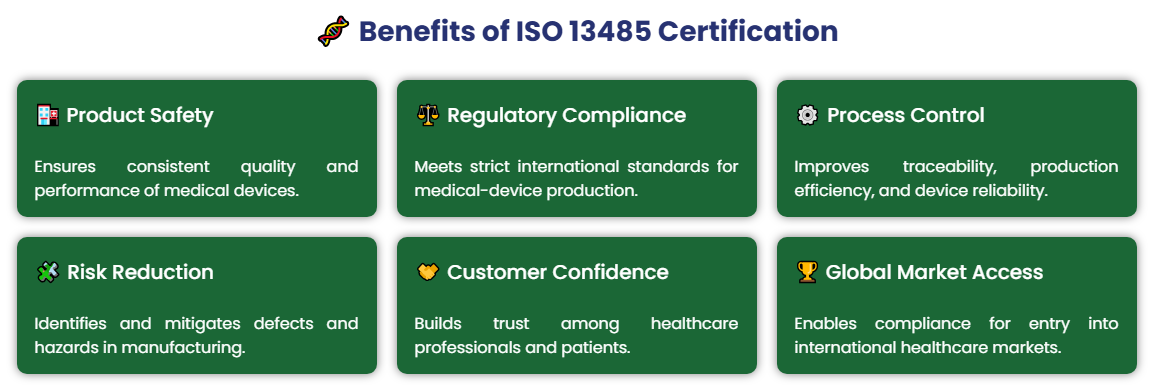

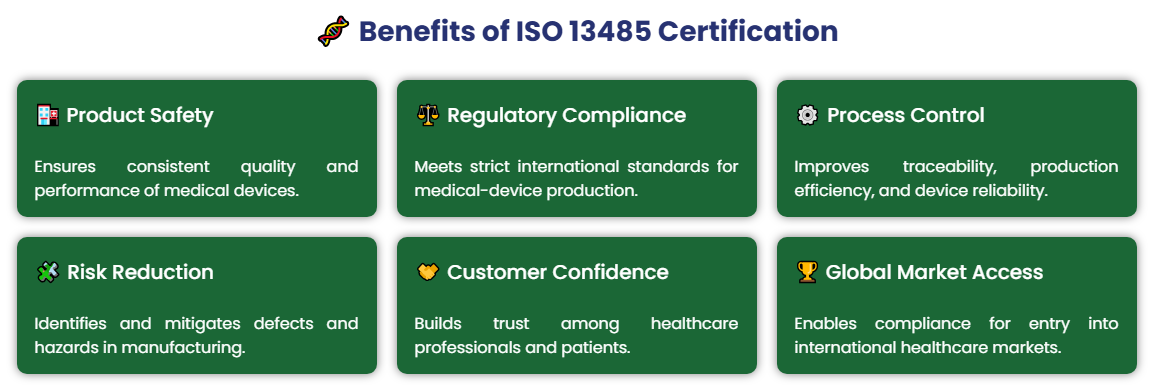

ISO 13485 For Aesthetic Injectables: Not Only a Quality System, But Also a Risk Management Tool

ISO 13485 is an international standard for the quality management system of medical devices, specifically designed for the characteristics of the medical device industry. In the field of cosmetic injections, the application of this standard is particularly important:

●Risk Management Runs Through The Entire Process

From product design and development to production and manufacturing, risk assessment and control are required at every stage. For Mesotherapy products, this means that a complete risk control mechanism needs to be established throughout the entire process, including raw material selection, production techniques, and sterilization processes. Especially, HA vs non-HA mesotherapy products have completely different risk considerations in formula design and require targeted control strategies.

●The Requirements For Traceability Are Becoming More Stringent

The standard requires the realization of full-chain traceability from raw materials to end users. Once quality problems occur, the source of the problem can be located in the shortest time to minimize the spread of risks to the greatest extent. This requirement is particularly important for private label mesotherapy opportunities. The brand owner needs to ensure that every link of contract manufacturing complies with traceability requirements.

●The Design Control Is More Rigorous

Product design must be based on sufficient scientific evidence and clinical data. Any design changes need to undergo strict verification and approval. This is directly related to the safety and effectiveness of the product.

GMP Compliance For Mesotherapy Suppliers: The Cornerstone Of Quality Assurance In The Production Process

Good Manufacturing Practice (GMP) is a production standard that ensures the safety and effectiveness of products. In the field of Mesotherapy product manufacturing, GMP requirements cover:

●Clean Production Environment

Injection-grade products must be produced in an A-level clean environment, with strict limits on the number of particles and microorganisms in the air. Take hyaluronic acid fillers as an example. The cleanliness requirement for the production environment is more than ten times that of the production environment for ordinary drugs.

●Strict Process Control

Each batch of products must have complete production records, including raw material batch numbers, production parameters, environmental monitoring data, etc. Any deviation needs to be recorded and the causes analyzed. This is crucial for ensuring the consistency of mesotherapy products.

●A Perfect Inspection System

From the raw materials entering the factory to the finished products leaving the factory, every link needs to undergo strict inspection. Especially for sterile products and implantable products, additional biocompatibility tests are required.

CE Marking For Mesotherapy Products: Passport To The International Market

●The Importance Of The CE Marking

With the increasingly strict global export regulations for cosmetic injectables, CE marking for mesotherapy products has become the basic threshold for entering the European market. Starting from 2025, the new MDR regulations will be fully implemented, putting forward higher requirements for clinical evidence and quality management systems

●The Technical Documents Require An Upgrade

More complete design documents, risk analysis reports and clinical evaluation data need to be provided.

●Post-Listing Supervision Has Been Strengthened

It is required to establish a more complete post-market supervision system and collect and analyze safety data in a timely manner.

●The Certification Cycle Has Been Extended

Due to stricter audits, the certification period may be extended from the original 6 to 8 months to 12 to 18 months.

Industry Status Quo And Development Trends

According To The Latest Market Research Report:

●The Market Is Highly Differentiated

HA vs non-HA mesotherapy products show different development trends. Hyaluronic acid products have maintained stable growth in the mid-range market thanks to their mature technology and reversible advantages. Non-hyaluronic acid products such as poly-L-lactic acid and hydroxyapatite have grown rapidly in professional markets and specific indication fields.

●The OEM/ODM Model Is Mature

OEM/ODM mesotherapy market trends show that this model is transforming from simple production contract manufacturing to comprehensive solution provision. A mature ODM supplier not only provides production services but also assists brand owners in completing the entire process of services such as product registration and market access.

●Globalization Of Regulation

With the increasing convergence of global export regulations for cosmetic injectables, the trend of one-time certification and global acceptance is becoming more and more obvious. Products that have passed the CE certification often enjoy a faster approval process when entering other markets.

Case Analysis Of Security Incidents: The Cost Of Non-Compliance

Case One: Microbial Contamination Incident

In 2023, the hyaluronic acid filler produced by a certain Asian manufacturer exceeded the microbial standard due to an unqualified production environment. Patients who used this product suffered from severe infections, and the enterprise eventually faced huge compensation and permanent loss of market share. This incident highlights the importance of GMP compliance for mesotherapy suppliers.

Case Two: CE Certification Has Expired

Although the Mesotherapy products of a certain brand have obtained the CE certificate, serious deficiencies in the quality management system were found during the subsequent supervision and audit, and the certificate was suspended. This not only led to the product being taken off the shelves in the European market, but also affected sales in other markets.

OEM/ODM Mesotherapy Market Trends: New Opportunities And New Challenges

With the intensification of competition in the medical aesthetics market, an increasing number of brands are choosing the OEM/ODM model. The latest trend shows:

●Service Content Expansion

Shift from simple production contract manufacturing to a "one-stop solution", including product research and development, registration application, marketing support, etc.

●The Technical Threshold Has Increased

The technical requirements for manufacturing enterprises are getting higher and higher, especially in terms of ISO 13485 for aesthetic injectables and GMP compliance for mesotherapy suppliers.

●The Demand For Customization Is Increasing

Brand owners are increasingly demanding product differentiation, which requires suppliers to have greater flexibility in research and development as well as production.

Industry Data And Statistics

According to the latest data from the International Society of Aesthetic Surgery:

●Enterprises certified by ISO 13485 for aesthetic injectables have a 65% reduction in the incidence of adverse product events.

●Enterprises with a high degree of GMP compliance for mesotherapy suppliers have a 78% lower market complaint rate than those with low compliance.

●products with CE marking for mesotherapy products are 40% faster in new market expansion.

●Enterprises that have established a quality system in accordance with the Mesotherapy Safety Guidelines 2025 have seen an average increase of 35% in customer satisfaction.

Expert Advice: How To Choose a Compliant Supplier

●Give Priority To The Certification Situation

Ensure that the supplier holds valid ISO 13485 and GMP certificates, which can be verified through the official website of the certification body. Special attention should be paid to the effectiveness and application scope of CE marking for mesotherapy products.

●Examine Technical Strength

Understand the R&D and production experience of the supplier in HA vs non-HA mesotherapy products, and evaluate whether its technical reserves meet the future development needs.

●Evaluate The Compliance History

Check whether the supplier has a record of violations or a history of product recalls, and understand the operational effectiveness of its quality management system.

●Consider The Potential For Long-Term Cooperation

For brands that hope to carry out private label mesotherapy opportunities, it is necessary to assess whether the supplier has a long-term and stable cooperation ability.

Future Outlook

As 2025 approaches, the medical aesthetics injection industry will face new opportunities and challenges:

●Regulatory Requirements Continue To Be Upgraded

Regulatory authorities of various countries will continue to raise the entry threshold, and the global export regulations for cosmetic injectables will be even stricter.

●Accelerated Technological Innovation

New materials and new processes are constantly emerging, which puts forward higher requirements for quality management.

●Market Differentiation Has Intensified

The high-end market pays more attention to evidence of safety and effectiveness, and the requirements for ISO 13485 for aesthetic injectables and GMP compliance for mesotherapy suppliers will reach a new height.

●The Degree Of Specialization Has Been Enhanced

All links from production to service will become more specialized, and the industry concentration is expected to further increase.

For practitioners, choosing compliant suppliers is not only a responsibility to patients but also an investment in the long-term development of the enterprise. Today, in the increasingly standardized medical aesthetics industry, compliance has become one of the core competitive advantages.

Industry Tip

●When choosing mesotherapy products, it is essential to verify the ISO 13485 for aesthetic injectables and GMP compliance for mesotherapy suppliers certifications of the suppliers

●Pay attention to the latest requirement changes of CE marking for mesotherapy products

●Update the internal quality management system in accordance with the Mesotherapy Safety Guidelines 2025

●Grasp the market trends of OEM/ODM mesotherapy and choose the appropriate cooperation model.